Modal

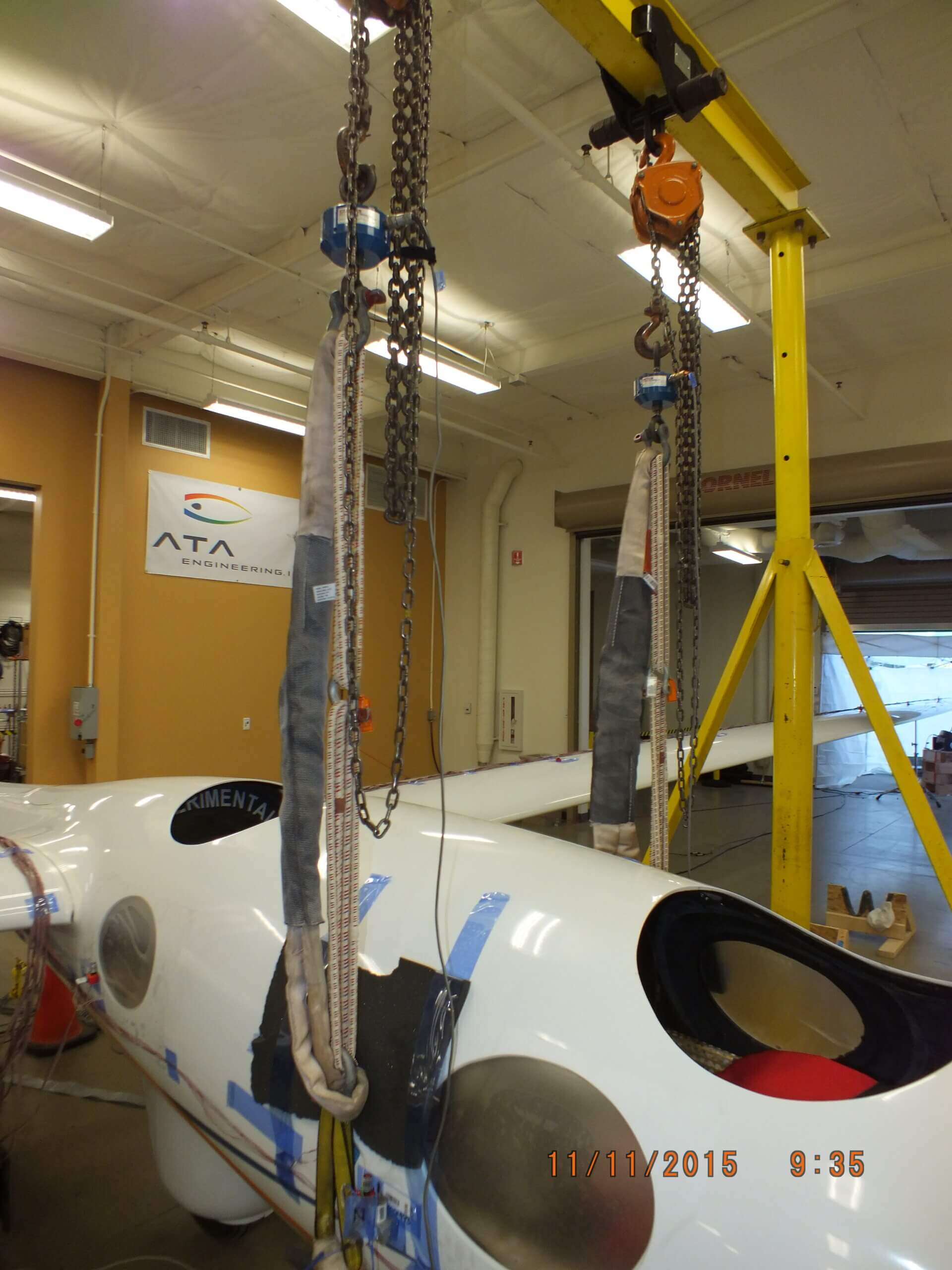

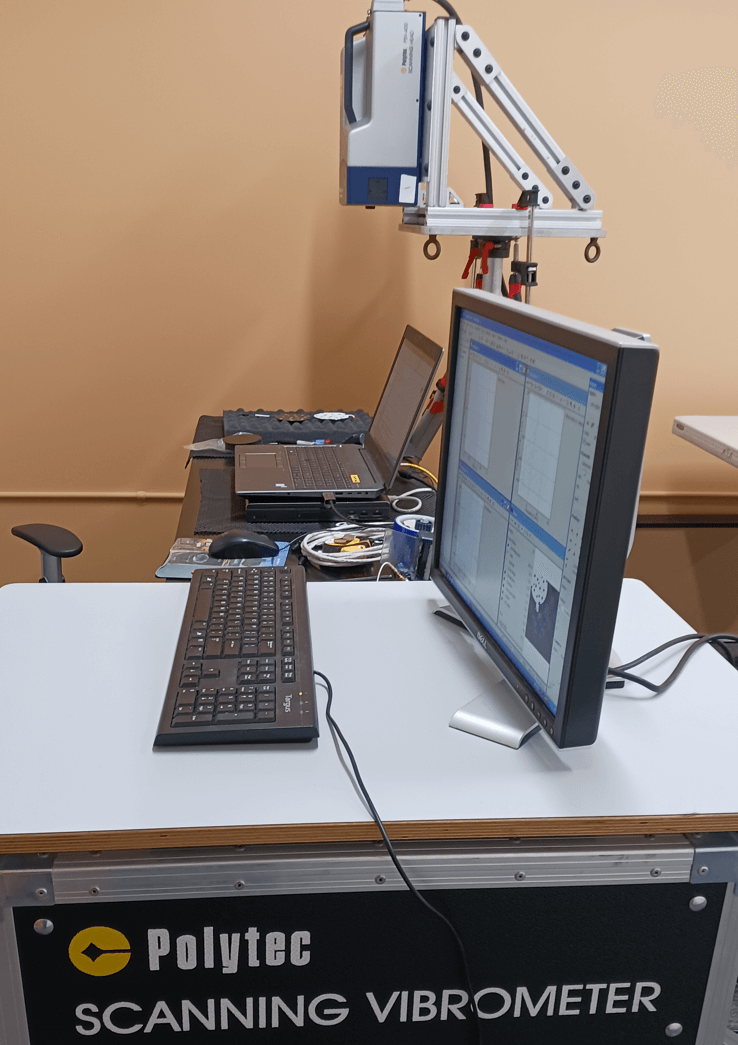

We have been providing this service for over 40 years, having pioneered numerous technical capabilities including random excitation, multishaker testing, polyreference data processing, and automated test setup processes. Our advancements in our patented Multi-Sine sweep excitation (U.S. Pat. No. 8,281,659), Alias-Free Polyreference (AFPoly) parameter estimation technique, and base shake modal application have all spearheaded improvements in the modal test field. Our ability to deploy well over 1000 channels of instrumentation and data acquisition equipment allows us to complete modal surveys of almost any size structure. We specialize in aerospace structures (aircraft, space launch vehicles, rocket motors, and satellites) but can test virtually any dynamic system.