Process Improvement

ATA has decades of experience across engineering disciplines using engineering software and data. New software methods can often be created to make processes faster and more accurate, more repeatable, and more reliable. Streamlining existing methods and processes can generate tremendous gains, and customizing software for specialized requirements can dramatically improve performance. Customization, configuration control, and traceability to design, analysis, and/or testing can also facilitate product and process development, and validating methods or models can create confidence in product engineering.

ATA has decades of experience across engineering disciplines using engineering software and data. New software methods can often be created to make processes faster and more accurate, more repeatable, and more reliable. Streamlining existing methods and processes can generate tremendous gains, and customizing software for specialized requirements can dramatically improve performance. Customization, configuration control, and traceability to design, analysis, and/or testing can also facilitate product and process development, and validating methods or models can create confidence in product engineering.

What We Can Do

ATA has a long history of helping customers and projects in developing software tools and engineering practices, models, and methods to meet emerging challenges for design, analysis, and testing. Below are some of the areas where ATA has specialized experience to help customers make improvements with engineering software:

Engineering CAD/CAE data translation

ATA has a long history of writing commercial and project-specific FEA translation and results processing utilities. Our software products and services can be used to read engineering analysis and test data quickly. We often help customers streamline their own processes for translating and comparing engineering data. We have done many projects to make it easier to translate CAD and product model data across engineering teams, and we have help customers solve issues with legacy data and data migration.

Engineering software customization

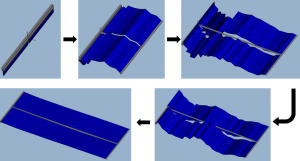

ATA has customized many commercial CAD and CAE and test software programs using APIs, macros, or stand-alone programs. Such customization can add new methods that are needed for analysis.

Engineering data management

ATA has experience managing large amounts of CAD, CAE, and test data, using PLM, Oracle, and MSQL to manage large amounts of engineering data and configure data access and security. ATA has supported several customers with exploring PLM systems such as Teamcenter.

Engineering modernization

ATA has experience with updating organization hardware and software for engineering, as well as training for deployment of updated CAD and CAE tools, exploring engineering workflows and use cases, and using HPC to queue, solve, and postprocess large models quickly.

Software for new products, manufacturing, and research

ATA has written software for solving specialized problems in research, SBIRs, hardware prorotype deployment, controls, and PLC automation.

Areas where ATA has helped customers improve processes have frequently included data translation, numerical methods with analysis or test, CAD and CAE modeling, meshing, model checking, model validation, and software or hardware testing.

ATA can help with engineering process development tasks and help conduct process pilot projects to audit engineering processes, review requirements, review design best practices, review and validate FE models and methods, implement new methods, create customized tools for CAD or CAE, and provide background on using HPC configurations with commercial FEA and CFD solvers. Process pilot projects or tasks can help research, explore, document, and quantify existing and proposed process improvements.