Free Resources

- ABOUT

- SERVICES

Design

Analysis

Test

- Software

Siemens Digital Industries Software

Technical Support Hotline

ATA Software

Software We Use

Process Improvement

- Industries

- PORTFOLIO

- Careers

- CONTACT

- PROJECT INQUIRY

Explore how Simcenter 3D is able to cut the development time of electronic powertrains by half with simulation and virtual verification.

The race to electrify the automotive mass market is on. As automakers strive to outpace competition and simultaneously meet stringent environmental regulations, the development of efficient, reliable, and increasingly affordable electric vehicles (EVs) is becoming critical. Reducing the development cycle times of e-Drives (e-Powertrains) from the traditional 3–4 years to just 2 years would be a game changer for automakers.

The race to electrify the automotive mass market is on. As automakers strive to outpace competition and simultaneously meet stringent environmental regulations, the development of efficient, reliable, and increasingly affordable electric vehicles (EVs) is becoming critical. Reducing the development cycle times of e-Drives (e-Powertrains) from the traditional 3–4 years to just 2 years would be a game changer for automakers.

Physical testing, a time- and cost-intensive part of e-Drive development, poses a significant bottleneck. Enter Simcenter 3D – the cutting-edge simulation software that is revolutionizing the way automakers approach e-Drive development. By replacing numerous physical tests with accurate simulations and virtual verification, Simcenter 3D dramatically accelerates the development process, ensuring faster time to market and significant cost savings.

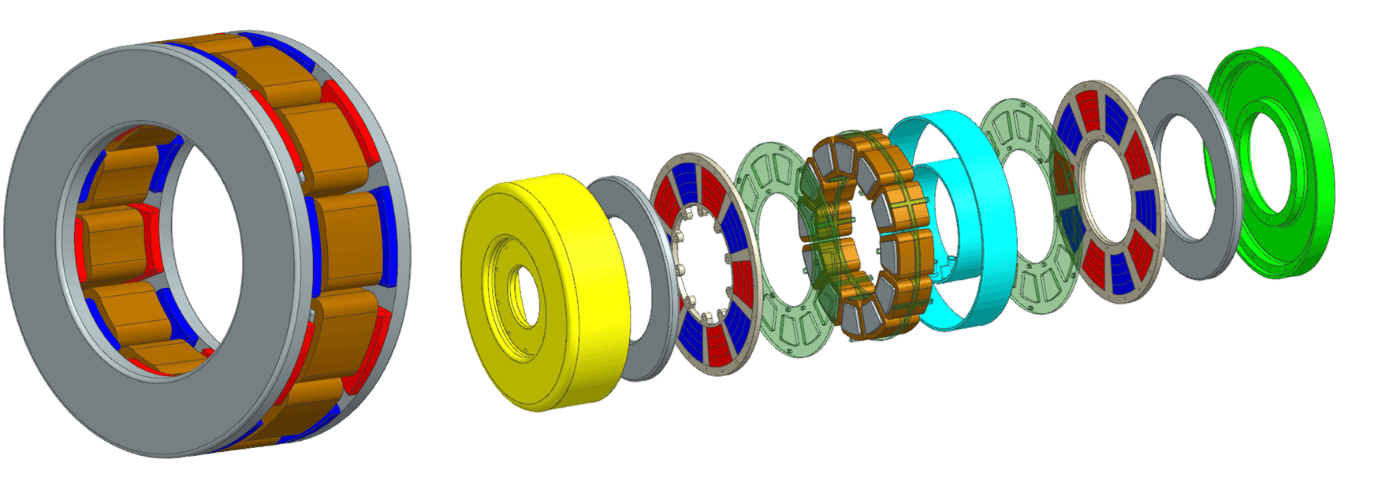

ATA Engineering invites you to an exclusive webinar showcasing how Simcenter 3D was used in the virtual verification of an axial-flux in-wheel traction motor. Learn how Simcenter 3D’s comprehensive suite of solvers and live connections to CAD that can process design updates in real time live links to a single design CAD facilitate an integrated workflow approach for multi-domain analyses, including electromagnetics (EMAG), computational fluid dynamics (CFD)-thermal, structural, and acoustics.

Key Takeaways:

Who Should Attend?

Why Watch?

Product Manager, Siemens Digital Industries Software